Automate your lights to save energy

Lighting automation is making the switching pattern of the lights automatic based on the actual requirements for lighting. When there is adequate daylight and or when there is no one to utilize the lighting from the electrical lights, automation switches off the electrical lights as they unnecessarily consume power. Automation of lights have numerous benefits. The lighting automation can be done in both electrical lights and daylights.

Automation in Electrical Lights

The electrical lights have occupancy sensor with them. These sensors sense the presence of a human by identifying the temperature difference in the atmosphere.When there is presence of a human, the lights gets switched on and gets switched off when there is no one.

Integration with daylights

Some electrical lights have sensors that also sense the adequate presence of daylight. If there is required amount of light available from the daylight, the electrical lights gets switched off automatically, thereby reducing the power consumption.

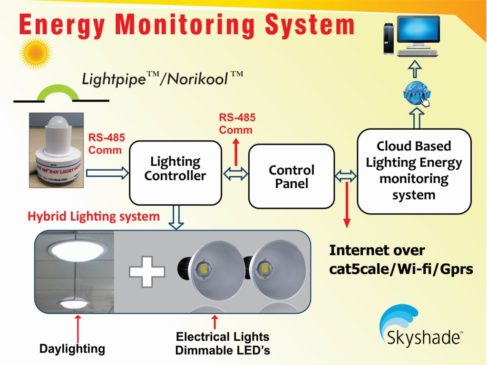

Daylight products also can be integrated with electrical lights. This integration happens through three components. It has three components namely sensor, lighting controller and the luminary control panel. The required lux level in the area is predetermined and set in the controller. As long as there is the required lux level from the daylights, the electrical lights remain switched off. When there is a decline in the lux level, the electrical lights gets switched on. This happens in a single step or in the multiple steps. In multiple steps the lights are grouped either in two or thee groups based on the number of electrical lights. The switching pattern of the electrical lights happen step by step. When there is slight decrease in the lux level from the daylights, the first group of lights gets switched on. As the lux level from daylight decreases, the subsequent group of lights get switched on step by step.

The entire automation sequence can be override by manual operations and also can be controlled through an cloud based energy monitoring system. The control panel stores the details of the energy saved.

The layout of one such automation system is given below.

Hybrid Daylights

In Hybrid daylights, Daylights and electrical LED Lights are built in a single system. The working is similar to other automated lights. However, the main difference is that the electrical lights and the daylights together make a single unit or product.

Automation in street lights

Street lights provide lights throughout the night. Most of the times at the night, there may not be a need for street lights to glow with full efficiency as there might less or no movement of people or vehicles. In such cases street lights can be equipped with motion sensors. These street lights glow with dim light when there is no movement and glows with full efficiency only when there is a movement. This helps in saving huge power as the street lights burn throughout the night.

Benefits of Lighting automation

- Lighting automation switches off unwanted electrical lights and switches on the lights when required, automatically. This eliminates the need for a manual work to switch off and on the lights.

- Automation helps to switch off the lights instantly, thereby reducing the power consumption up to 75%.

- Since the lights are switched on as soon as the u level gets reduced, there is no question of being in dark even for a second.

- A better lighting in the work place will result in increase in effectiveness of the workers.

- The production need not be stopped for the want of the lighting.

- The overall production cost comes down due to the reduced electricity bills

- The life span of the electrical lights increase as their work load is reduced due to automation.

- Te reduced use of electrical lights reduce the total heat build up in the workspace, thereby reducing the power consumed by cooling devices such as air conditioners

Thus the automation of electrical and daylights not only reduce power consumption, but also optimize the overall operational cost.

Products with Lighting ControllersView All

-

Skyshade 45 Amps Dimming Lighting Controller

₹66,428.81 – ₹72,143.22 Select options This product has multiple variants. The options may be chosen on the product page

-

Skyshade Lighting Controller

₹52,143.22 – ₹62,143.22 Select options This product has multiple variants. The options may be chosen on the product page